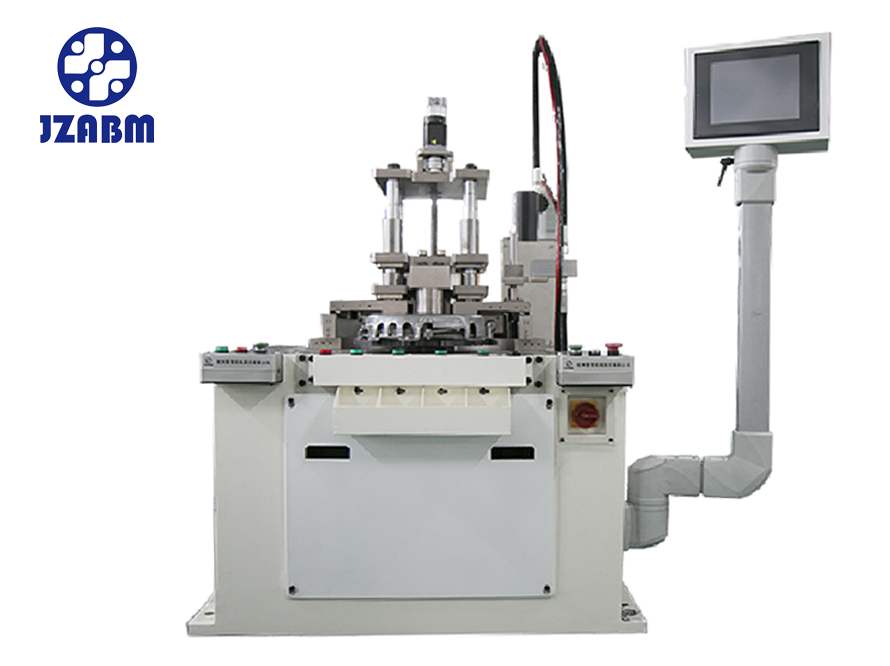

Automatic Clutch Cover Balancing Machine

Menu

Automatic Clutch Cover Balancing Machine

Clutch components are typically balanced with drill, mill or laser cutting correction although other correction methods are available such as welding. All correction methods have intelligent feedback ensuring high quality unbalance correction, increased machine throughput and reduced rejects.

PRODUCT FEATURES

- It is suitable for clutch workpieces with a diameter of φ300-φ500mm for automobile clutches.

- Single-sided balance, welding balance weight with balance, quick model change, parameter adjustment, simple operation and strong compatibility.

- Welding aggravated features.

- Use carbon dioxide shielded welding to weld the balance weight to the specified position of the clutch workpiece.

TECHNICAL PARAMETERS

|

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com