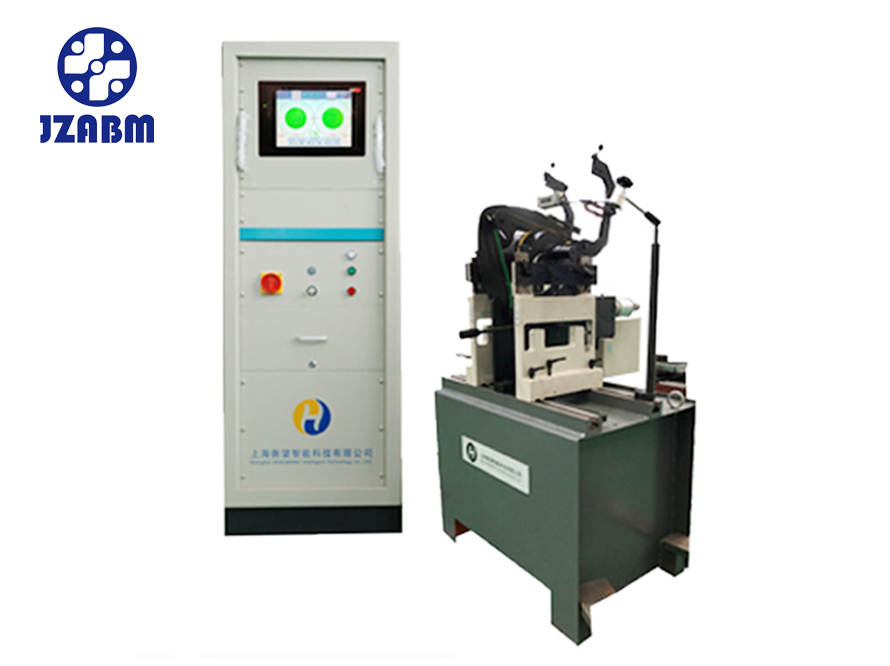

Crankshaft Universal Balancing Machine

Crankshaft Universal Balancing Machine

Crankshaft Universal Balancing Machine with Special designed brackets can effectively transmit mechanical force . The durable and reliable sensor possesses high sensitivity & permanent calibration brings high accuracy

Description

our crankshaft universal balancing machine is especially suitable for balance detection of small and medium motor rotors, small and medium turbocharger rotors, automotive air conditioner rotors, small machine tool spindles, fan rotors, etc. This machine adopts the combination of belt drive and AC motor. It has the characteristics of high precision, high efficiency, simple operation, intuitive display and strong human-computer interaction ability.

PRODUCT FEATURES

- Integral H-shaped support frame, light and reliable structure, small vibration system damping and good rigidity.

- Each accessory part adopts international and domestic well-known brand products, such as gearboxes, rolling bearings, low-voltage electrical components, etc.

- Strict and complete quality system, complete technology, testing methods and configuration of various metal processing equipment to ensure product quality.

- Perfect comprehensive supporting capabilities, can provide flexible and diverse options, and provide you with the most optimized product configuration.

TECHNICAL PARAMETERS

| Machine model | H2BK | H20BK | |

| Maximum mass of workpiece | 40kg | 100kg | |

| Maximum diameter of workpiece | Φ800mm | ||

| Distance between two supports | 80~630mm | ||

| Workpiece shaft diameter range | Standard type | Φ8~Φ50mm | Φ9~Φ70mm |

| Extended type (optional) | Φ100mm | Φ140mm | |

| Diameter range of ring belt transmission | Φ20~Φ200mm | ||

| Balance speed (when the diameter of the workpiece is Φ 100 mm) | 0~1540r/min | ||

| Motor power | 0.75kW(AC) | ||

| Maximum indication sensitivity of electric measuring box | CAB590 | 1.5g·mm | 2.4g·mm |

| (when balance speed > 820r / min) | CAB690 | 0.5g·mm | 0.8g·mm |

| Bed length | Standard bed | 750 mm | |

| Optional bed | 1500/3000 mm | ||

| Limit value | Support stiffness GN2kg / min2) | 27×106 | |

| Driving power Gd2n2(KGM2/ min2) | 3.94×106 | ||

| Minimum achievable residual unbalance emar | 0.5gmm/kg | 0.1gmm/kg | |

| Unbalance reduction rate | 90% | 90% | |

Remark: Based on actual specifications (can be negotiated according to customer’s requirement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com