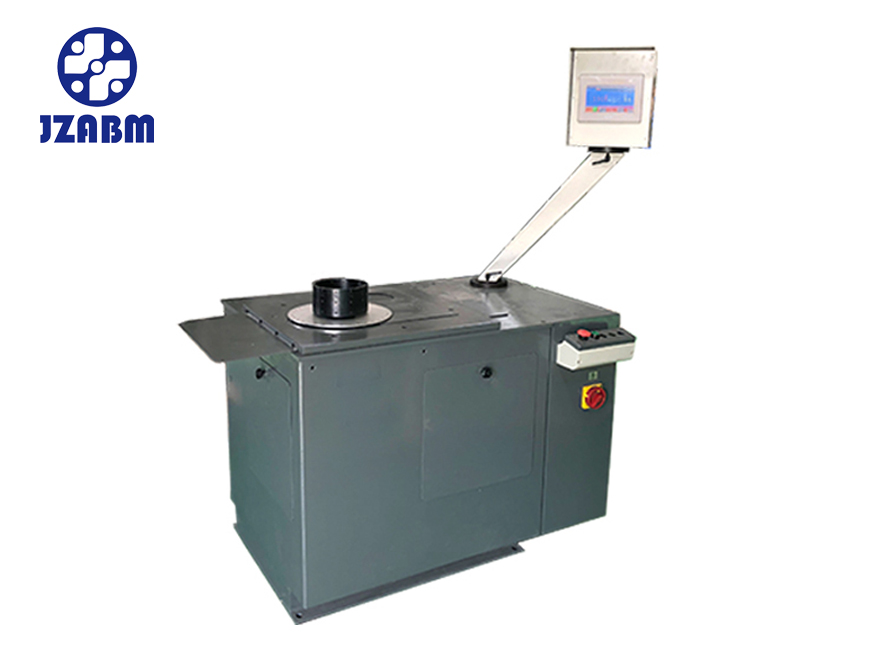

Clutch Component Balancing Machines

Clutch Component Balancing Machines

Clutch Component Balancing Machines 1.Dynamic balancing machines for all industries and rotor types.

2.Manual and automatic dynamic balancing machine solutions for varying production demands.

3.Integrated unbalance correction through drilling, milling, welding etc.

Description

Clutch Component Balancing Machines are applied to balance detection of various disc-shaped workpieces, such as automobile clutch, brake drum, brake disc, flywheel, fan, fan, impeller of feed pump, etc., which are widely used at present.High precision, high efficiency, easy to operate, intuitive display, good stability, when man-machine dialogue, they have several major characteristics.As long as these series machines are operated by simple calibration program before start-up, they can accurately and quickly display the balance detection of the inspected workpiece after one start-up operation.

These series machines are equipped with various de weight devices, workpiece centering fixtures and dust collection devices according to the needs of users, which can further improve the work efficiency of the balancing machine.

PRODUCT FEATURES

- Simple to use software with intuitive unbalance correction displays.

- Each accessory part adopts international and domestic well-known brand products, such as gearboxes, rolling bearings, low-voltage electrical components, etc.

- Strict and complete quality system, complete technology, testing methods and configuration of various metal processing equipment to ensure product quality.

- Perfect comprehensive supporting capabilities, can provide flexible and diverse options, and provide you with the most optimized product configuration.

TECHNICAL PARAMETERS

| RLD-0.5 | RLD-3 | RLD-10 | RLD-30 | RLD-100 | RLD-300 | |

| Maximum mass of workpiece (including fixture) | 0.5 kg | 3 kg | 10 kg | 30 kg | 100 kg | 300 kg |

| Maximum diameter of workpiece | 150 mm | 250 mm | 400 mm | 1000 mm | 1000 mm | 1400 mm |

| Maximum diameter of the workpiece providing the safety cover | 150 mm | 250 mm | 400 mm | 600 mm | 640 mm | |

| Balance speed | 2500 r/min | 2400 r/min | 1200 r/min | 800 r/min | 530 r/min | 260 r/min |

| Motor power | 0.09 kW | 0.25 kW | 0.55 kW | 1.5 kW | 2.2 kW | 7.5 kW |

| Minimum achievable residual unbalance | 2 g·mm/kg | 2 g·mm/kg | 2 g·mm/kg | 2 g·mm/kg | 2 g·mm/kg | 2 g·mm/kg |

| Unbalance reduction rate (URR) | ≥90% | ≥90% | ≥90% | ≥90% | ≥90% | ≥90% |

| Survey plan book | 1 | 1 | 1 | 1 | 1 | 1 |

| Model of measuring box | CAB641 | CAB641 | CAB641 | CAB641 | CAB641 | CAB641 |

Remark: Based on actual specifications (can be negotiated accroding to customer’s requiement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com