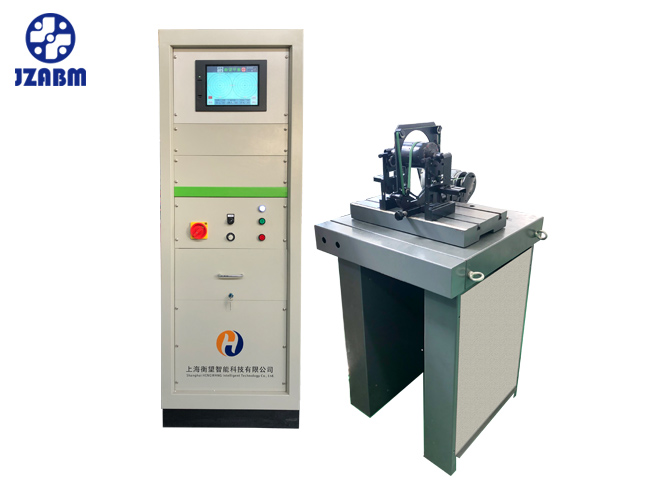

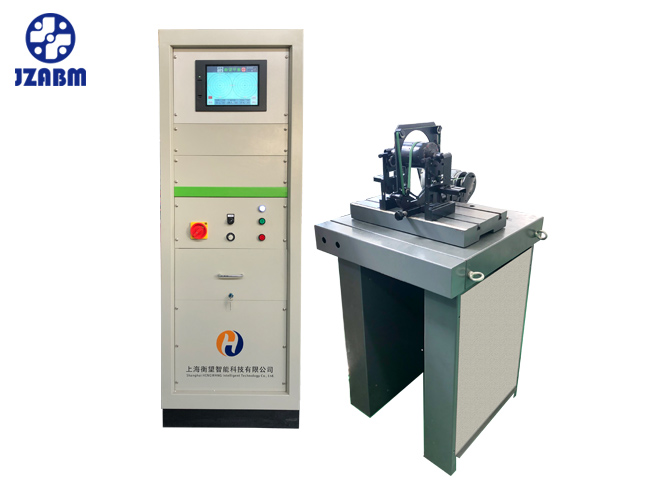

Horizontal Balancing Machine

Horizontal Balancing Machine

Horizontal Hard Support Balancing Machine is one of the most advanced general-purpose horizontal balancing machines with independent intellectual property rights integrating precision machinery.

Description

The H series hard-bearing balancing machine is one of the most advanced general-purpose horizontal balancing machines with independent intellectual property rights integrating precision machinery and modern electrical technology. Because of its simple operation, stable performance and precise detection accuracy, it is widely used in industries such as motors, fans, water pumps, printing, papermaking, textile machinery, internal combustion engines, electronics, machine tools and aerospace.

This machine is especially suitable for the balance detection of small motor rotors, small blower rotors, small and medium machine tool spindle rotors, etc. This machine adopts the combination of loop belt + AC motor, which drives the workpiece to rotate through the loop belt. It has the characteristics of high precision, high efficiency, simple operation, intuitive display, and strong human-computer interaction. Before starting, just adjust according to the distance between the two correction surfaces of the rotor, the distance between the correction surface and the supporting point, and the radius of the correction surface, and the magnitude and phase of the workpiece imbalance can be correctly displayed in one start.

PRODUCT FEATURES

- Integral H-shaped support frame, light and reliable structure, small vibration system damping and good rigidity.

- Each accessory part adopts international and domestic well-known brand products, such as gearboxes, rolling bearings, low-voltage electrical components, etc.

- Strict and complete quality system, complete technology, testing methods and configuration of various metal processing equipment to ensure product quality.

- Perfect comprehensive supporting capabilities, can provide flexible and diverse options, and provide you with the most optimized product configuration.

TECHNICAL PARAMETERS

| Parameter model | H1BK | H10BK |

| Weight range | 10 kg | 16 |

| Maximum diameter of workpiece | 360 mm | |

| Diameter range of belt drive | 10-150 mm | |

| The distance between the two supports from the drive flange to the right support center | 36 mm-450 mm | |

| Axle journal range | Standard:φ5-φ22 mm | Standard:φ6-φ30 mm |

| Extend:φ22-φ50 mm | Extend:φ30-φ70 mm | |

| Balance speed (when the diameter of the workpiece is φ100mm when dragging) | 0-1500 r/min | |

| Motor power | 0.22 kw | |

| Min achievable residual imbalance remar | ≤0.1 g.mm/kg | |

| Maximum indicating sensitivity of HW210 electrical measuring box | 0.15 g.mm | 0.3 g.mm |

| Maximum indicating sensitivity of HW210 electrical measuring box (When the balance speed is >820 r/min) | 0.05 g.mm | 0.1 g.mm |

| Unbalance reduction rate URR | ≥95% | |

Remark: Based on actual specifications (can be negotiated according to customer’s requirement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com