Armature Production Line

Menu

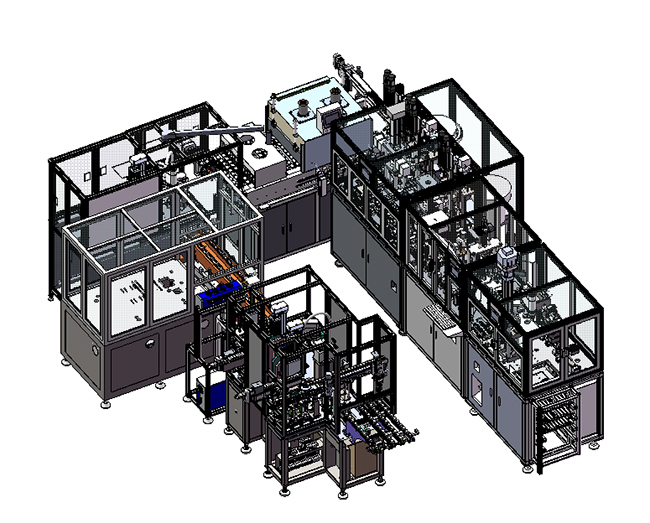

Armature Production Line

1. Adopt the material frame to load materials, feed the material more once, one person can easily see all the line;

2. Connect the original single machine to reduce labor;

VIDEO PRESENTATION

PRODUCT FEATURES

- Adopt the material frame to load materials, feed the material more once, one person can easily see all the line.

- Connect the original single machine to reduce labor.

- The 6-axis robot is used to transport the rotor, which is flexible and high-precision, and it is not easy to damage the rotor during the handling process.

- Wide range of application and quicker model change.

- Fault alarm prompt, easy maintenance.

- When a failure occurs, it will automatically alarm and stop, which is convenient and safe to handle.

- The main electrical components adopt international first-line brands, and the equipment performance is stable and reliable.

- Fully independent intellectual property rights, special products can support highly customized solutions.

TECHNICAL PARAMETERS

| Item | Technical data |

| Equipment name | Transformation of the robot for the front and rear armature line |

| Main components | Cylinder: SMC,Airtac |

| Servo motor: SIEMENS | |

| Sensor: KEYENCE, OMRON, Kerui,Panasonic | |

| Touch screen: Proface | |

| Control PLC: SIEMENS1200 | |

| Step motor: Moons | |

| Stack of rotor:20-60mm | |

| Rotor range | Diameter of rotor: Φ25-50mm |

| Power | AC380V |

| Pneumatic | 0.4~0.6Mpa |

| Cycle time | 20s (May fluctuate depending on the rotor process) |

Remark: Based on actual specifications (can be negotiated according to customer’s requirement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com