Automatic Stator Winding Machine

Menu

Automatic Stator Winding Machine

1. Manual loading and unloading;

2. Automatic winding (two axis synchronous winding);

3. Automatic start and end line processing (3D platform, guide needle can move in 3D);

PRODUCT FEATURES

- Manual loading and unloading

- Automatic winding (two axis synchronous winding)

- Automatic start and end line processing (3D platform, guide needle can move in 3D)

- Automatic slot change (bridge line processing, 3D platform, guide needle can move in 3D)

- Scissors mechanism (after the end of thick line treatment, the scissors mechanism is used to automatically cut the thread)

- The operation area adopts safety grating + two hands start, double protection

- Friendly man-machine interface, direct programming with touch screen

- Standard servo tension control

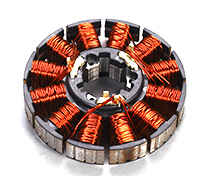

STATOR SAMPLE

TECHNICAL PARAMETERS

| Two-station Automatic stator winding machine | |

| Item | Parameter |

| Equipment Name | Two-station automatic stator winding machine |

| Model | RXN02 |

| Main configuration | PLC:Yaskawa, Leadshine |

| HMI: Proface, Artrich | |

| Sensor:Contrinex、OMRON、KEYENCE、Panasonic | |

| Drive Motor:Yaskawa | |

| Cylinder:SMC | |

| Stator stack length | ≤100mm |

| Winding diameter range | 0.2mm-1.2mm |

| Power | Three-phase380V(±5%) |

| Working air pressure | 0.5-0.6 Mpa |

| Number of axes | 2 |

| Winding speed | ≤400 turns/min |

| Wire length deviation | ≤2mm |

| Diameter size | 997x 1320x1923mm |

| Weight | 800kg |

Remark: Based on actual specifications (can be negotiated according to customer’s requirement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com