COMPOSITE INDUSTRIES

INTRODUCTION

there is very good definition about Composites in Wikipedia that says ;

” A composite material is a material which is produced from two or more constituent materials. these constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. within the finished structure , the individual elements remain separates and distinct, distinguishing composites from mixtures and solid solutions.”

But here , in our products portfolio we notice Fiber Reinforced Polymers ( Plastics ) or FRP machinery and technologies technologies .

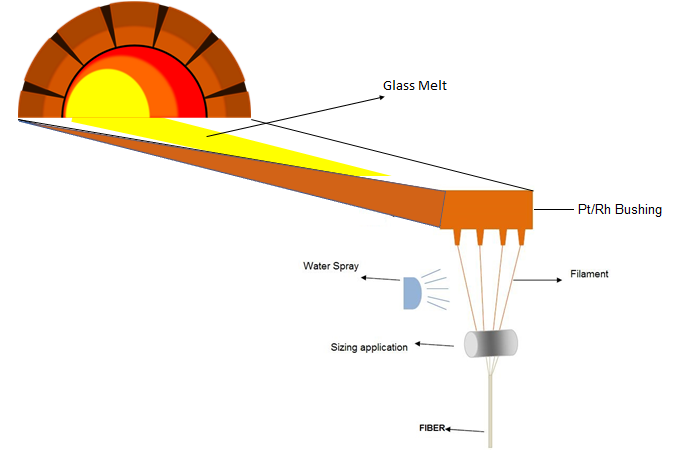

- Glass Fiber Production Line

According customer request it is possible to design the production line for producing “E” or “C” or “ECR” glass, the line is as a complete line along with technology transfer including :

- Raw material store

- Raw Material transferring channels

- Furnace

- Bushings

- Sizing applicator unite

- Yarn winding

- Unites for producing Rovings ,Chopped Strands and …

- Drying blowers

- Packaging & Transportation

Machinery for producing MATs

Machinery for producing several kinds of MATs with different capacities, widths and weight can be supplied as follows :

- Chopped Strand Mat production line

- Continuous Filament Mat Production Line

- Surface Mat ( tissue ) production line

- Combow Mat machinery

- Stitched Mat machines

Woven Roving machinery

- Plain Weaving Machine

- Unidirectional Weaving machine

GRP,GRV,GRE Pipe & Fittings production machinery

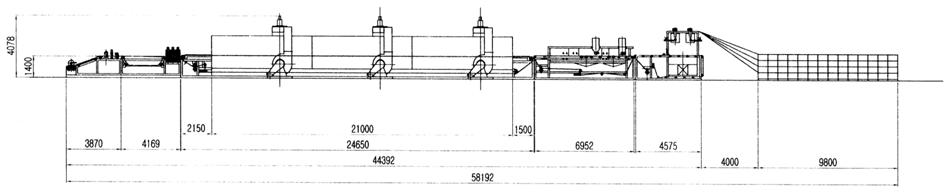

– GRP pipe production by Continuous Filament Winding technology

In this method , it is possible to produce GRP & GRV pipes by Polyester & Vinyl Ester resins from 300 mm Dia up to 4000 mm Dia in high speed , complete line includes :

1. Resin and Mortar storage tanks

2. Roving Creels

3. Continuous Filament Winding machine

4. Pipe cutting device

5. Pipe holding trolley

6. Coupling ( sleeve ) production machine

7. Coupling ( sleeve ) grinding & chamfering device

8. Coupling connection device

9. …

– GRP pipe production by Discontinuous Filament Winding Technology

By this method it is possible to produce GRP, GRV & GRE pipes from 25 up to 6000 mm Dia and machinery are supplied in two types , Single Mandrel & Multi Mandrel ( MT4,MT6,MT8), the line can include :

1. Resin & Mortar storage tanks

2. Glass creels

3. Discontinuous Filament winding machine

4. Pipe holding trolley

5. Cutting – Grinding machine

6. Fitting production machine

– Test machines of a GRP Pipe production Plant

1. Hydrostatice Machine for pipes

2. Hydrostatice machine for Fittings

3. Hydrostatice Machine for Couplings

4. Stiffness Test machine

5. Tensile Test machine

6. …

Pultrusion & Pulwinding

Pultrusion machine is suitable for producing FRP profiles such as Rods , Angles , Ts and …., Pultrusion machines based on their Pulling Force and Pulling Device ( Caterpillar or Hand to Hand ) are classified and we can supply both according customer request . A Pultrusion machine includes following parts :

- Glassfiber creels

- Resin bath

- Preformers

- Dies

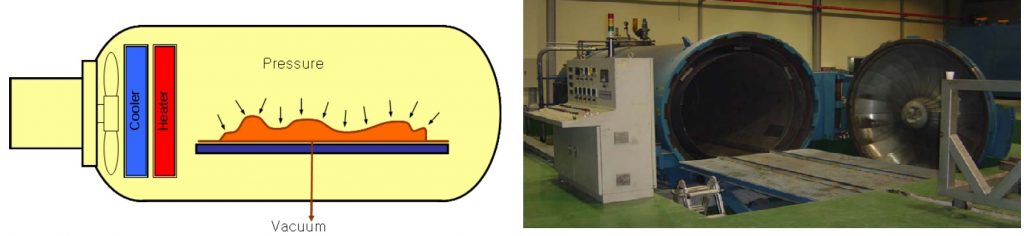

Autoclave & Hydroclave

Autoclave & Hydroclave mostly are used for special composite parts for special cases in aerospace and military applications. To quote an Autoclave machine following items must be clarified :

- Working Pressure

- Working Temperature

- Part Dimensions

- Heating Source

- Pressurizing Source

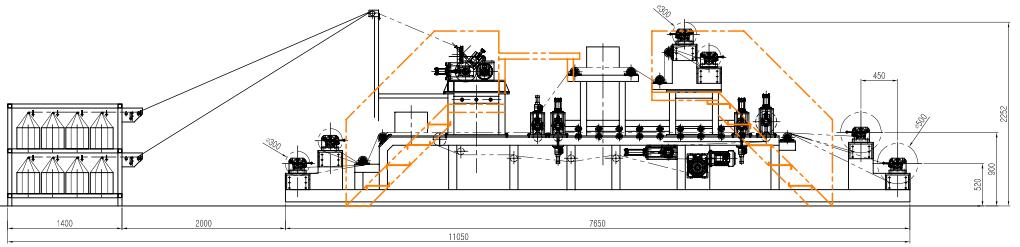

Sheet Molding Compound ” SMC” machine

To produce composite parts in high quantities and with high speed , SMC is the best method , here again we can supply different kinds of SMC machines to produce molding compound as a sheet roll with different thickness and different widths . also if special press machines are needed we can provide you suitable price , suitable quality machines.

Prepreg

The Prpereg is an abreviation of preimpregnated materials .Matrix is intermediate material of composite material product by of sheet from that make impregnation beforehand to reinforced fiber. Reinforced fiber are used

carbon fiber, glass fiber, Aramid fiber etc. mainly and bonding material are used epoxy resin, polyester resin, thermoplastic resin etc.

Composite material that produced using prepreg is used variously in production of space-air industry, general industry, sports, leisure, car article etc. because can improve various special quality of strength, stiffness, corrosion resistance, fatigue life, wear resistance, impact resistance, weight reduction etc. Unidirectional prepreg machine is to produce prepreg by sheet from making impregnated to epoxy resin after arrange reinforced fiber by one-way. and making impregnated resin to woven fabric .Like this, produced prepreg makes composite material product that quality is very excellent by method of manufacture of vacuum forming, mold forming,

autoclave forming, rolling etc.

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com