POLYOL

Polyether Polyols

Polyether polyols are produced by the alkoxylation process. An addition reaction takes place where ethylene oxide or propylene oxide reacts with an initiator containing OH- groups like glycerin, saccharose and other carbohydrates. the reaction takes place with a catalyst which is fed into the solution in a batch reactor. Using a different catalyst, a continuous process can be followed. The reaction runs under elevated temperature and pressure and is strongly exothermic. The amount of alkoxylation species can be varied to achieve different chain lengths and molecular weights.

Main organic oxide utilized are ethylene oxide , propylene oxide , butylene oxide , epichlorohydrin. Main glycols utilized are ethylene glycol , propylene glycol, water, glycerin, sorbitol, sucrose and THME.

Polyether polyols have high resistance to hydrolysis. They are usually in the form of colorless liquids, insoluble in water but soluble in most organic solvents.

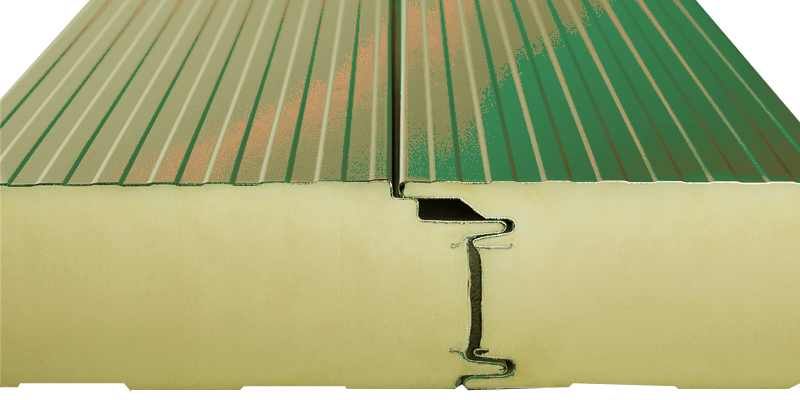

There are two main types of polyether polyols, short chain polyether polyols and long chain polyether polyols. Short chain polyether polyols combined with MDI are used to produce rigid foams, while long chain polyether polyols combined with TDI resulting in flexible foams, consequently Polyether polyols’ major use is in polyurethane foams. Flexible foams are primarily used in cushioning applications such as furniture, bedding and car seats, flexible molded foams , elastic block foams and in carpet underlay. Rigid foam’s largest consumer is the construction industry where it is mostly used for insulation, PU sandwich panels, cast coatings . Rigid foam is also used in commercial refrigeration and packaging. Smaller uses for polyether polyols include elastomers, adhesives and sealants, surface coatings and polyurethane fibers. Meanwhile some other non polyurethan applications for polyether polyols that are used as lubricants for specialist compressors, liquids for metalworking, hydraulic fluids and transmission oils.

Polyester Polyols

Polyester polyols are made by the polycondensation reaction of multifunctional carboxylic acids and polyhydroxyl compounds. The desired product of polyester polyol synthesis is a polyester with high levels of terminal hydroxyl functionality. Achieving this goal is facilitated by applying the Carothers equation for determining the ratio of acidic and alcoholic monomers to get the desired molecular weight and hydroxyl functionality .Within polyurethan production ,polyester polyols are the a key feedstock in coatings , adhesives , elastomer and rigid foam formulations .depending on the application , an aromatic or aliphatic diacid will be employed to deliver the desire suite of properties . aromatic polyesters are usually deployed for the purpose of enhancing flame retardance , increased Tg, and reduce gas permeability and so are widely used in polyurethane insulation foams. Aliphatic polyesters used in urethane formulation will enhance tensile strength , abrasion resistance , UV resistance , and low temperature flexibility and find primary use in coatings and elastomers.

Seed Oil-Derived Polyols

Whereas most polyols are originally derived from C2 and C3 components of natural gas, the use of seed oils provides an additional source of hydrocarbon with either intrinsic hydroxyl functionality or with an olefin reactive handle to create isocyanate reactive groups. Many seeds can be sued such as soybean , cotton seed , canola and castor. Castor oil is a unique substrate since it is the triglyceride of ricinoleic acid, which, is already hydroxyl functionalized. This allows the unmodified castor oil to be used in some applications with no thermochemical transformation required. Normally to create functionality on the seed oil internal olefin bonds for use in polyurethane chemistry some methods such as Epoxidation , Ring Opening and Ozonolysis are used and the most simple one is ring opening. Bio-based polyols can be used in producing polyurethan foams , coating , adhesives . The seed oil polyester polyols provide environmentally friendly , or green , coating formulations with low volatile organic compound emissions which lead to coatings with superior physical properties, such as exceptional hydrolytic resistance and flexibility. From these polyester polyols, waterborne polyurethane dispersions are also developed with excellent stability resulting in coatings with superior physical properties such as good toughness , high abrasion resistance and exceptional hydrolytic and acid resistance.

Other Polyols :

Polyether and polyester polyols are the most common polyols but there are some other polyols available that their use is not so high and are used for special applications such as Polycarbonate Polyols , Polyacrylate Polyols , styrene–acrylonitrile (SAN)-filled

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com