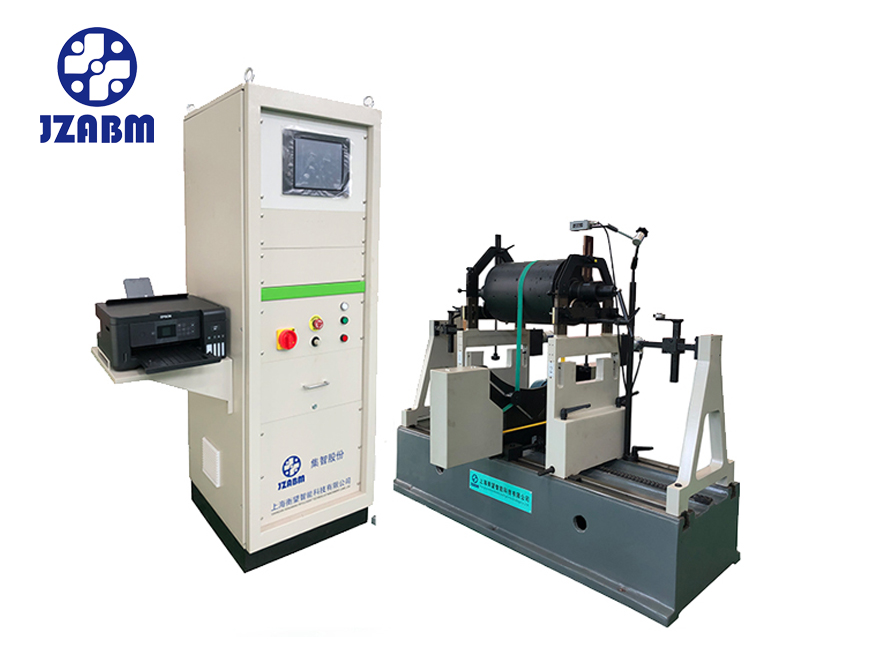

Pump Rotor Balancing Machine

Pump Rotor Balancing Machine

this machine is especially suitable for the balance detection of medium-sized motor rotor, water pump rotor, centrifuge rotor, small and medium-sized blower rotor, small and medium-sized machine tool spindle rotor, medium-sized textile machine winding rotor, etc

Description

pump rotor balancing machine adopts the combination of belt drive and AC motor. It has the characteristics of high precision, high efficiency, simple operation, intuitive display and strong human-computer interaction ability.Before start-up, as long as the distance between the two calibration faces of the rotor, the distance between the calibration front and the support point, as well as the radius of the calibration front, can correctly display the magnitude and phase of the workpiece unbalance under one start.

PRODUCT FEATURES

- Adopts the combination of belt drive and AC motor.

- Has the characteristics of high precision, high efficiency, simple operation, intuitive display and strong human-computer interaction ability.

- Strict and complete quality system, complete technology, testing methods and configuration of various metal processing equipment to ensure product quality.

- Perfect comprehensive supporting capabilities, can provide flexible and diverse options, and provide you with the most optimized product configuration.

TECHNICAL PARAMETERS

Remark: Based on actual specifications (can be negotiated according to customer’s requirement)

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com