SANDWICH PANEL LINE

INTRODUCTION

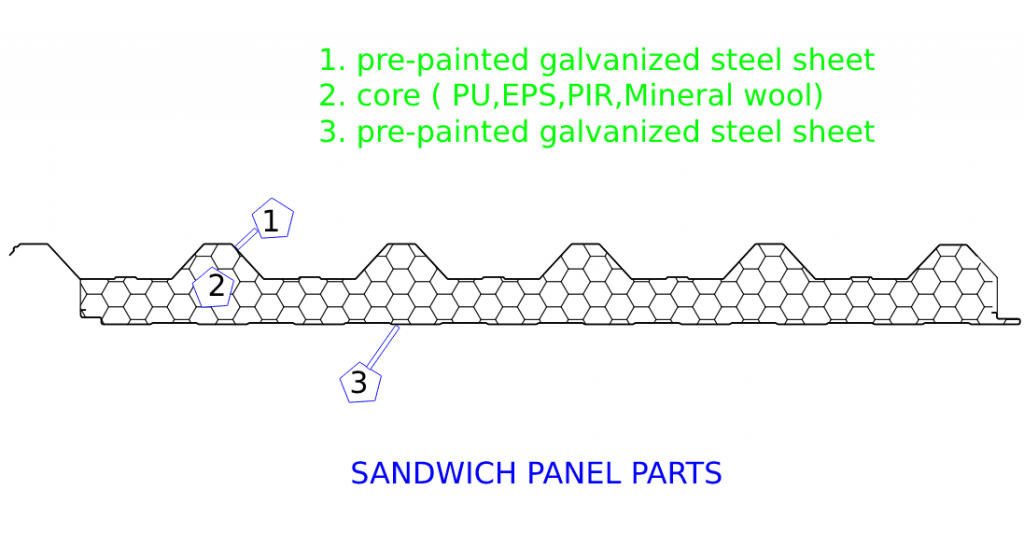

Now a days , sandwich panels are very popular solution for obtaining insulation for buildings specially in countries that the whether is so warm or so cold.

There are many advantages by selecting sandwich panels since with this products construction is far less complicated and thus quicker and cheaper . sandwich panels are multifunctional that can be used as wall or roof cover and also can be used for clod rooms .

ROCK WOOL SANDWICH PANEL

Continuous PU/PUR/PIR Sandwich Panel Production Line

The whole system includes uncoiling system, film covering and cutting system, roll forming machine ,preheating oven, high pressure foaming system, double belt conveyor, double belt heating device, cutting system, etc. Uncoiler will uncoil the steel sheet which goes to the roll forming machine. Then the upper and down roll formed panel will go to the double belt press machine while the PU foaming machine inject the PU inside at the same time. After 24m movement and heating, they will get sticked and come out of the press machine. Then the cutting machine will cut the panel into pieces. Then it can goes for the packing.

Working flow

Dolly feeding coil — Uncoiling material — Film covering (cutting) —Roll forming — Preheating material—Foaming — Laminating in double belt conveyor — Cutting product—Run out conveyor —- Cooling product — Automatic stacking product.

Machine Specifications

Item | Parameter | |

Applicable Raw Material | Type | Color steel, Galvanized sheet, Aluminum sheet |

(mm) Thickness | 0.2-0.8 | |

(Mpa) Width | ≤1250 (Max) | |

Specifications of Producible Sandwich Panel | (mm) Length | 2000-16000 |

(mm) Width | 600-1200 | |

(mm) Thickness | 30-200 (Not including height of corrugation) | |

(m/min) Production Speed | 3-10 (Adjustable) | |

(mm) Valid length of double belt conveyor | 16000-36000 | |

(Bar) Work pressure on pouring foam | 150-200 | |

(KW) Total power | About 300 | |

(mm) Total Size (Length x Width x Height) | 130000 x 15000 x 6000 | |

Continuous PU/PUR/PIR Sandwich Panel Production Line

Discontinuous PU/PIR Sandwich Panel Production Line (10M ,2+2 ) is designed with leading technology. The press machine adopts gantry lift-draw type, locates directly without any foundation. 2+2 type saves much time for panel preparation and discharge time which increase times of efficiency. At the same time, the high quality working tables offer the best ensure for good quality sandwich panel. Bidirectional trolley adopts separate float guide rails with some advantages like mutual noninterference, accurate location and easy operation.

Working process:

The multi-layer press system is composed by a main press machine and rail brackets mounted on both sides. Press machine includes upper and down two load-mold-boards . Each side rail bracket on the press also remains one load-mold-board . When production :

Step 1: Put upper and down steel sheets into the mold frame on the load-mold-boards ; seal the edge and coat mold-release agent ,etc.

Step 2: Two load-mold-boards enter the main press machine at the same time by driving force. Meanwhile , two load-mold-boards inner the press machine move out and stay on the rail bracket .

Step 3: Press machine closes. Inject PU/PIR raw material into each layer , at the same time , PU/PIR foaming and aging

Step 4: After 10-30 minutes (according to PU/PIR material and operation experience), lift the press, move the molding frame, then get the PU/PIR sandwich panel, Non-slip pedals, Electric control system, etc.

The main points of our Discontinuous PU/PIR Sandwich Panel Production Line ( 10M , 2+2 ):

●Components High Pressure Polyurethane Foaming Machine

●Product size :10000 x 1000 mm

●Panel thickness: 40-150mm (Adjustable)

●Capacity : Around 600-800m2/day(as 8 hours), around 150,000-200,000m2 /year (as 250 work days).

if you have any question about product detail please

MARKETING POLE GROUP

Central Office TEL: 0098 5138407354

Email : info@marketingpole.com